In today's development of artificial intelligence (AI), data transmission speed has become an important bottleneck restricting its progress. To break down this barrier, a research team led by the University of Michigan (UM) is developing a new chip connection system that uses light waves instead of traditional cables for data transmission. This innovation is expected to solve the "memory wall" problem that limits computing speed and promote further growth of AI models.

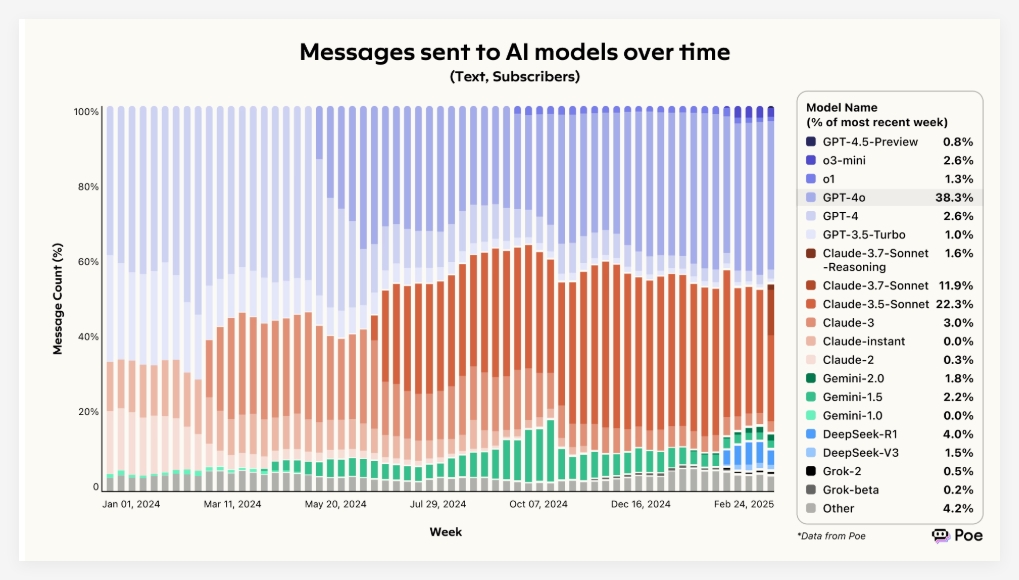

The project received $2 million in funding from the National Science Foundation's Future Semiconductors Program and involved the University of Washington, the University of Pennsylvania, Lawrence Berkeley National Laboratory, and four industry partners including Google, Hewlett Packard Enterprise, Microsoft, and Nvidia. Although data processing speed has increased 60,000 times in the past 20 years, the data transmission speed between computer memory and processor has only increased 30 times. This disproportionate increase makes data transmission the biggest obstacle to the expansion of AI models.

"Our technology enables high-performance computing to keep pace with ever-growing data flows," said Di Liang, the project's principal investigator and UM professor of electrical and computer engineering. "With optical connections, we expect to achieve tens of terabits per second." The data transmission speed is more than 100 times faster than that of current electrical connections.”

Currently, data transfers between multiple memory and processor chips rely on metal connections, which has severe speed and bandwidth limitations. As the scale of AI models continues to expand, the current hard-wired connection model can no longer meet demand. The research team's new design will use the transmission characteristics of light to transmit data between chips through channels called optical waveguides, greatly improving data transmission efficiency.

Another highlight of the new technology is its reconfigurability. The researchers plan to use special phase-change materials that change their refractive index when stimulated by laser light or voltage, allowing flexible adjustment of the light path. As project co-author Professor Liang Feng of the University of Pennsylvania said: "Just like opening and closing roads, if companies adopt this technology to produce chips, they can rewrite the layout of other components without changing the layout of other components. Connections between different batches of chips and servers.”

In addition, the research team will develop a flow control software that monitors which chips need to communicate in real time so that connections can be adjusted on the fly. This flexible connection method not only improves data processing efficiency, but can also be dynamically adjusted according to different AI model requirements.

The program will also provide UM students with the opportunity to work with industry, allowing them to gain valuable hands-on experience in a rapidly evolving technology field. Professor Li said: “Collaboration with industry allows students to better understand modern